Coal Industry

The company can customize the required filter cloth for users in the coal industry. The filter cloths produced by the company are widely used in various physical separation and filtration process sections in the coal industry, and are suitable for drum machines, belt filters, vertical leaf filters, and horizontal leaf filters in related industries including coal plants. Machines, flipping machines, flattening machines, and all other models.

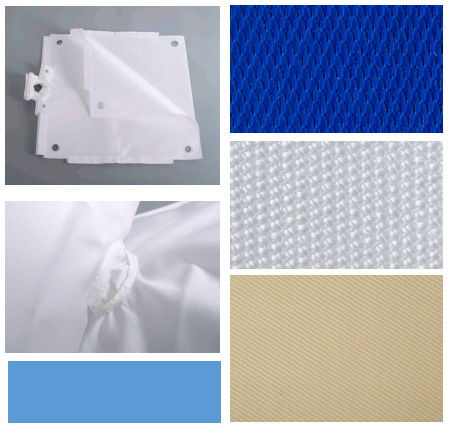

The main product types of our filter cloth:

The filter cloth is the heart of the filter press. The quality of the filter press fabric directly affects the filtering effect of the filter press. Moreover, both filter cloth and processing level are indispensable. Our filter press filter cloth is mainly medium and thick fabric, including polyester, polypropylene and other materials, monofilament filter cloth, imported double-layer filter cloth, etc., and has an independent high-quality processing workshop, and according to the fineness of the material , the company launched 400 mesh, 800 mesh, 2000 mesh and other monofilament filter cloths to meet the various filtration precision requirements of the coal industry.

Our product advantages

Filter cloth processing:

According to the size and special requirements of each customer, such as brushed filter cloth, embedded filter cloth, hanging filter cloth, plate and frame filter cloth, filter cloth hemming, filter cloth punching, etc., we can process according to samples and drawings. .

Filter cloth application:

Widely used in chemical, metallurgy, petrochemical, pharmaceutical, food, mining, coal, ceramics, environmental protection and other fields, suitable for various types of filter presses such as plate and frame, box type, diaphragm, etc.

Effect:

1. Improve productivity and reduce cycle time; 2. Remarkably improve cake removal effect; 3. Effectively reduce cleaning frequency; 4. Clear filtrate; 5. Dry filter cake, very good labor efficiency.

Selection basis:

A. Peeling performance of filter residue:

It directly affects the working efficiency of the filter press equipment. The surface of the filter residue is smooth and non-adhesive, and the filtrate will quickly seep out from the filter cloth. The filtration time is short and the efficiency is high. On the contrary, the filter residue is sticky, and the filtration time will be long, and the efficiency will of course be reduced accordingly. And the stronger the adhesion, the lower the efficiency. At this time, we will choose monofilament filter cloth or satin weave filter cloth.

B. According to the acidity and alkalinity of the filtrate:

Choose the filter cloth that suits you with different pH levels. The stronger acid resistance is polyester filter cloth, and the stronger alkali resistance is the vinylon filter cloth. Polypropylene filter cloth is also resistant to acid and alkali.

C. Wear resistance of filter material:

The shape of the filter residue, whether the particles are uniform, and whether the shape is hard, so as to consider the wear resistance of the filter cloth. The size is uneven, and there are edges and corners, which are selected according to the different degrees. The ones with better wear resistance are polyester filter cloth and nylon filter cloth.

Special filter cloth for coal industry:

The special filter cloth for the coal industry is generally used in the filter press of the coal plant. Working conditions (for reference): Alkali concentration: 0-320g/L Slurry flow: 0-180m³/h

Recommended model:

Material: Nylon PA

Model: PA1422/PA1426 (monofilament filter cloth)

Air permeability: 1000L/㎡/s

product features:

1. Excellent acid and alkali resistance and high tensile strength.

2. After shaping treatment, it is smooth and flat, with better air permeability and water permeability.

3. Tough and durable, the filter cake is easy to peel off and easy to regenerate.

4. The interface is sewn with acid and alkali resistant high-strength thread, which is durable.